Innovating the Future: Exploring 3D Print Manufacturing Companies

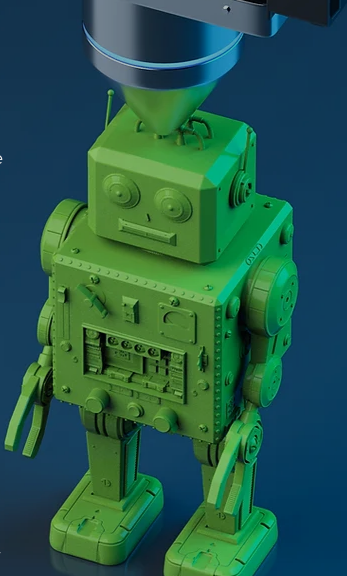

In the ever-evolving landscape of manufacturing, 3D printing technology has emerged as a revolutionary force, transforming the traditional paradigms of production. This comprehensive guide delves into the realm of 3D print manufacturing companies, uncovering their role in shaping industries, driving innovation, and ushering in a new era of possibilities. From additive manufacturing capabilities to diverse applications across sectors, understanding the landscape of a manufacturing company is paramount for those seeking cutting-edge solutions and pushing the boundaries of what’s possible.

The Rise of 3D Print Manufacturing Companies:

As the global manufacturing sector continues to embrace the digital age, manufacturing companies have become pivotal players in this technological renaissance. These companies harness the power of additive manufacturing, a process that builds objects layer by layer, offering unparalleled flexibility, precision, and design freedom. The impact of 3D printing extends across various industries, including aerospace, healthcare, automotive, and beyond.

Unleashing the Potential of Additive Manufacturing:

Prototyping and Rapid Iteration:

3D Printing Enterprises excel in providing rapid prototyping solutions. The ability to swiftly translate digital designs into physical prototypes accelerates product development cycles. Companies can iterate designs in real-time, facilitating faster innovation and reducing time-to-market for new products.

Customization and Personalization:

Additive manufacturing empowers 3D print companies to offer unparalleled customization and personalization options. From personalized medical implants to bespoke consumer products, this technology enables the creation of unique, tailored solutions that meet individual needs with precision.

Complex Geometries and Lightweight Structures:

Traditional manufacturing methods often face limitations when dealing with intricate geometries and lightweight structures. 3D Printing Enterprises overcome these constraints, producing complex components with minimal material waste. This capability is particularly valuable in industries where lightweight, high-strength structures are essential.

Applications Across Industries:

Aerospace and Defense:

In the aerospace and defense sector, 3D printing plays a transformative role. Companies utilize additive manufacturing to produce lightweight components for aircraft, spacecraft, and defense systems. The ability to create complex, integrated parts contributes to increased efficiency and reduced overall weight.

Healthcare and Biotechnology:

Print manufacturing companies are revolutionizing healthcare by producing patient-specific implants, prosthetics, and even organs through bioprinting. The customization afforded by 3D printing allows for precise medical interventions, improving patient outcomes and driving advancements in the field.

Automotive and Transportation:

The automotive industry leverages 3D printing for prototyping, tooling, and producing complex components. Manufacturing companies contribute to the creation of lightweight, fuel-efficient vehicles, while also enabling the customization of automotive parts for performance optimization.

Key Advantages of Choosing 3D Printing Enterprises:

Cost-Effective Prototyping:

Traditional prototyping processes can be costly and time-consuming. Print manufacturing companies offer cost-effective prototyping solutions, enabling businesses to iterate designs without the financial burden associated with traditional methods.

Reduced Material Waste:

Additive manufacturing minimizes material waste by building objects layer by layer. This eco-friendly approach aligns with sustainable manufacturing practices, making 3D Printing Enterprises attractive to those prioritizing environmental responsibility.

Faster Time-to-Market:

The rapid prototyping capabilities of 3D printing contribute to faster time-to-market for new products. This speed advantage is particularly crucial in industries where staying ahead of the competition is paramount.

Complex Design Possibilities:

Traditional manufacturing methods may struggle with intricate designs and complex geometries. 3D Printing Enterprises embrace the freedom of design offered by additive manufacturing, enabling the production of components with intricate details and complex structures.

Navigating the Landscape of 3D Print Manufacturing Companies:

Technological Expertise:

When considering 3D Printing Enterprises, assessing their technological expertise is essential. Companies with a deep understanding of various 3D printing technologies, such as stereolithography (SLA), selective laser sintering (SLS), and fused deposition modeling (FDM), are better positioned to meet diverse manufacturing needs.

Material Capabilities:

The range of materials a 3D print manufacturing company can work with is a critical factor. Different applications may require specific material properties, from high-strength thermoplastics to biocompatible materials for medical applications. A versatile company with a broad material portfolio provides flexibility for diverse projects.

Quality Assurance Processes:

Ensuring the quality of 3D-printed components is paramount. Reputable 3D Printing Enterprises implement robust quality assurance processes, including thorough inspections, testing, and adherence to industry standards. Certification and compliance with relevant regulations further validate the company’s commitment to quality.

Strategic Collaboration and Partnership:

Ecosystem Integration:

3D Printing Enterprises often thrive through strategic collaboration within a broader ecosystem. Collaborations with design firms, material suppliers, and technology developers create a synergy that enhances overall capabilities. This integrated approach allows companies to tap into a diverse pool of expertise, fostering innovation and staying at the forefront of technological advancements.

Research and Development Initiatives:

Leading 3D print manufacturing companies invest significantly in research and development initiatives. This commitment to R&D ensures that the company remains at the cutting edge of additive manufacturing technologies. Ongoing exploration of new materials, printing techniques, and process optimizations contributes to a continuous cycle of improvement and innovation.

Global Reach and Scalability:

Global Manufacturing Network:

Established 3D Printing Enterprises often have a global manufacturing network. This expansive reach allows them to cater to diverse markets and industries. A global presence enhances their ability to serve clients with localized manufacturing solutions, reducing lead times and logistical complexities.

Scalable Production Capacities:

Scalability is a key consideration for businesses looking to engage with 3D Printing Enterprises. Leading players in the industry have scalable production capacities, enabling them to handle projects of varying sizes. Whether it’s prototyping a single component or producing a batch of customized products, scalability ensures flexibility in meeting client demands.

Quality Control and Certification:

ISO Certification and Standards Adherence:

Reputable 3D Printing Enterprises prioritize quality control and often hold ISO certifications. Adherence to international standards is indicative of a commitment to quality and reliability. Clients can have confidence in the manufacturing processes, material specifications, and final product quality when working with a company that upholds rigorous standards.

Iterative Quality Improvement:

Quality control is not a static process; it is an ongoing commitment to iterative improvement. Leading 3D Printing Enterprises implement feedback loops, data analytics, and customer insights to refine their quality control processes continually. This dedication to improvement ensures that clients receive not only high-quality products but also benefit from a company’s commitment to excellence.

Customer-Centric Approach:

Customization and Client Consultation:

A customer-centric approach is a hallmark of successful 3D print manufacturing companies. These companies prioritize client consultations to understand unique requirements fully. The ability to offer customization aligns with the diverse needs of clients across industries, from aerospace to healthcare, fostering long-term partnerships based on mutual success.

Responsive Communication Channels:

Effective communication is essential in the collaborative process between 3D Printing Enterprises and their clients. Companies that maintain responsive communication channels ensure that clients are informed at every stage of the manufacturing process. Clarity, transparency, and timely updates contribute to a positive client experience.

Sustainability Initiatives:

Environmentally Friendly Practices:

Sustainability is increasingly becoming a focal point for businesses and consumers alike. Leading 3D Printing Enterprises integrate environmentally friendly practices into their operations. This may include the use of recyclable materials, energy-efficient processes, and a commitment to reducing carbon footprints. Clients seeking sustainable manufacturing solutions find alignment with companies that share these values.

Circular Economy Contributions:

Beyond minimizing waste, some manufacturing companies actively contribute to the circular economy. This involves the recycling and repurposing of materials, minimizing the environmental impact of manufacturing processes. Engaging with companies that embrace circular economy principles aligns with broader sustainability goals.

Conclusion: Pioneering the Future of Manufacturing with 3D Printing

In the dynamic landscape of modern manufacturing, 3D print manufacturing companies stand as pioneers, pushing the boundaries of what’s achievable. Their role in driving innovation, reducing production costs, and offering unparalleled customization positions them at the forefront of industry transformation. For those embarking on a journey to harness the potential of additive manufacturing, exploring the capabilities of 3D Printing Enterprises is not just a choice; it’s a strategic imperative.