The Impact of Aluminum Die Casting on Sustainable Manufacturing

In today’s manufacturing landscape, sustainability has become a paramount concern. As industries strive to reduce their environmental footprint, China Aluminum Die Casting emerges as a solution that offers both efficiency and eco-friendliness.

In this blog, we will explore the impact of aluminum die-casting on sustainable manufacturing practices. From its energy efficiency to waste reduction capabilities, we’ll delve into the benefits it brings.

Join us as we examine real-world case studies showcasing the positive environmental impact of China Aluminum Die Casting.

What is Aluminum Die Casting?

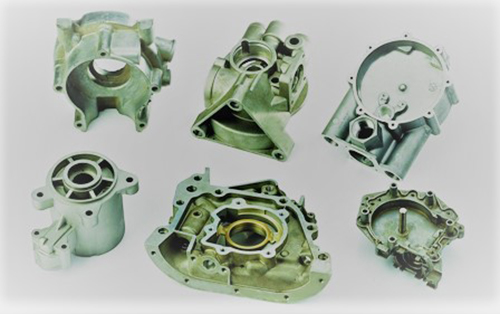

Aluminum die casting is a manufacturing process that involves injecting molten aluminum into a mold under high pressure. This technique allows for the creation of complex and lightweight parts with exceptional dimensional accuracy.

Unlike other manufacturing methods, China aluminum die casting offers numerous advantages:

It is highly cost-effective, enabling mass production at a fraction of the cost of alternative techniques.

Furthermore, die casting provides excellent design flexibility and allows for intricate shapes and thin walls.

Environmental Benefits of Aluminum Die Casting

Aluminum die casting offers a wide array of environmental benefits, positioning it as a highly sustainable choice for manufacturing processes. Let’s delve into the following advantages in detail:

1. Recyclability: Aluminum is an exceptionally recyclable material that can be recycled indefinitely without losing its inherent properties. This attribute allows for the continuous reuse of aluminum without needing primary extraction. By recycling aluminum, manufacturers contribute to conserving natural resources and minimizing energy consumption associated with extraction and production.

2. Energy Efficiency: Compared to alternative manufacturing methods, aluminum die casting stands out for its remarkable energy efficiency. The process requires significantly less energy for heating and cooling operations, leading to substantial energy savings. Reduced energy consumption lowers production costs and decreases carbon emissions, fostering a greener and more sustainable manufacturing industry.

3. Waste Reduction: The closed-loop system inherent in die casting is a key factor in waste reduction. It enables the efficient collection and reuse of scrap materials generated during the casting process. Manufacturers can minimize waste generation and contribute to a circular economy by capturing and reintroducing these materials into the production cycle. Additionally, the precise nature of die-casting techniques reduces the need for secondary machining operations, further optimizing material efficiency and minimizing overall waste.

4. Lower Emissions: Manufacturers actively contribute to reducing greenhouse gas emissions by adopting aluminum die casting. The energy-efficient nature of the process results in lower energy requirements, which leads to decreased emissions. Thus, by minimizing the environmental impact associated with manufacturing operations, China Aluminum Die Casting aids in mitigating climate change and advancing sustainable practices.

5. Resource Conservation: Aluminum die casting’s lightweight properties significantly contribute to resource conservation efforts. As lightweight aluminum components find application across various industries, such as automotive and aerospace, the overall energy consumption associated with transportation and operation decreases. This reduction in energy demand conserves valuable resources and fosters greater efficiency in resource utilization.

6. Longevity and Durability: Aluminum boasts excellent durability and longevity, ensuring that die-cast parts have an extended lifespan. This durability reduces the need for frequent replacements, minimizing material consumption and waste generation. Hence, manufacturers reduce their environmental impact and enhance the overall sustainability of their products by utilizing long-lasting die-cast components.

Manufacturers can play a pivotal role in sustainable manufacturing practices by harnessing the environmental benefits offered by China Aluminum Die Casting. In simple terms, embracing aluminum die casting enables manufacturers to contribute significantly to pursuing sustainable development and a more environmentally conscious industry.

Remember that promoting resource conservation, waste reduction, energy efficiency, and the longevity of products are crucial steps toward building a greener and more sustainable future.

Advancements in Technology and Innovation

Continuous advancements in technology have further enhanced the sustainability of aluminum die casting. Computer-aided design (CAD) and simulation software are vital in optimizing designs, reducing material waste, and improving production efficiency.

Innovative techniques such as vacuum-assisted die casting and squeeze casting offer even greater sustainability benefits by minimizing defects and enhancing material properties. These advancements continue to drive the adoption of aluminum die-casting in industries prioritizing sustainable manufacturing practices.

Final Thoughts

With environmental benefits, waste reduction capabilities, and energy efficiency, aluminum die casting emerges as a sustainable manufacturing solution. By embracing this technique, industries can reduce their environmental footprint while achieving cost savings and superior product quality. So, embrace aluminum die-casting solutions from China Casting Orlando and drive a greener future for manufacturing.